Advanced Ceramic in Semiconductor Industry

Advanced Ceramic in Semiconductor Industry

Ceramic Semiconductor Process Equipment Components

Ortech supports the ceramic semiconductor manufacturing industry by supplying ceramic materials and chamber-critical components used in chip-processing equipment. From raw material design and production to finished and assembled components, our vertically integrated manufacturing ensures quality for every step of the process. We also offer clean room (class 1000) packaging services to ensure high cleanness requirements of precision parts applied in semiconductor industry upon delivery to your facility.

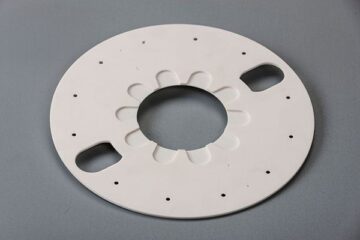

Wafer Handling and vacuum wafer chucks

As a leader in technical ceramics for wafer processing equipment, Ortech understands advanced semiconductor manufacturing and constantly develops new materials, designs, and processes to optimize yields and extend product life. Our ultra-flat ceramic vacuum wafer chucks improve yield management for semiconductor wafer processing. Low-surface-contact configurations minimize risk of back-side particles negatively affecting wafer geometry for precision applications.