Sample Projects

Manufacture of Technical Ceramics

Ortech provides high performance state-of-the-art ceramic materials manufactured by the most cost-effective processes. From quick-turn prototype development to high-volume production.

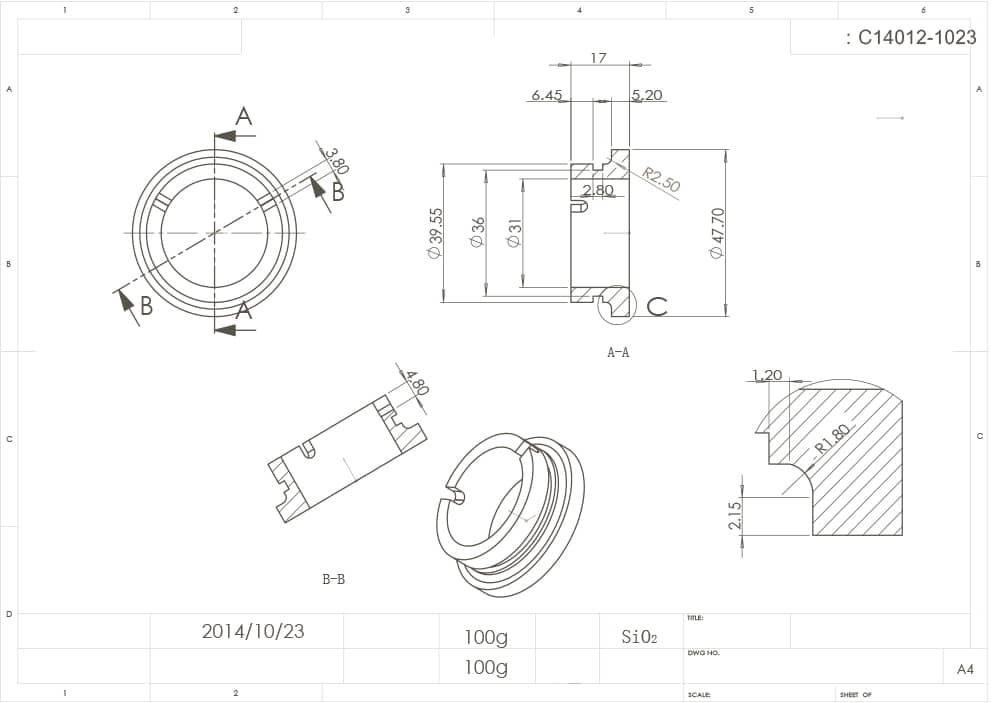

Ortech manufactures a great variety of advanced silicon carbide that is formed in two ways, reaction bonding and sintering. Silicon carbide is the …

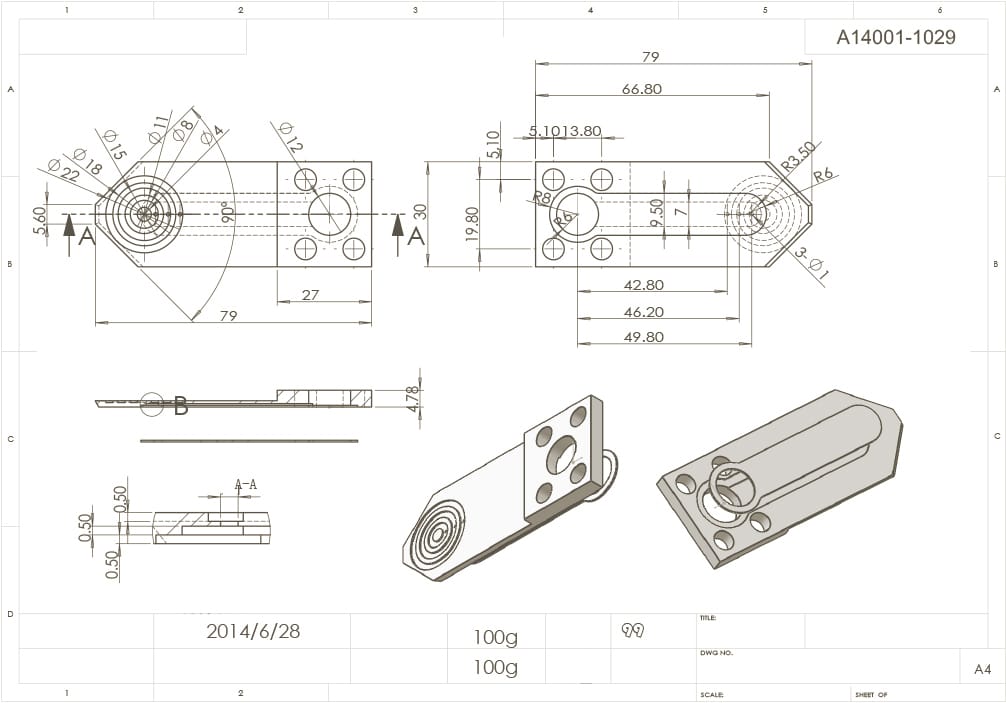

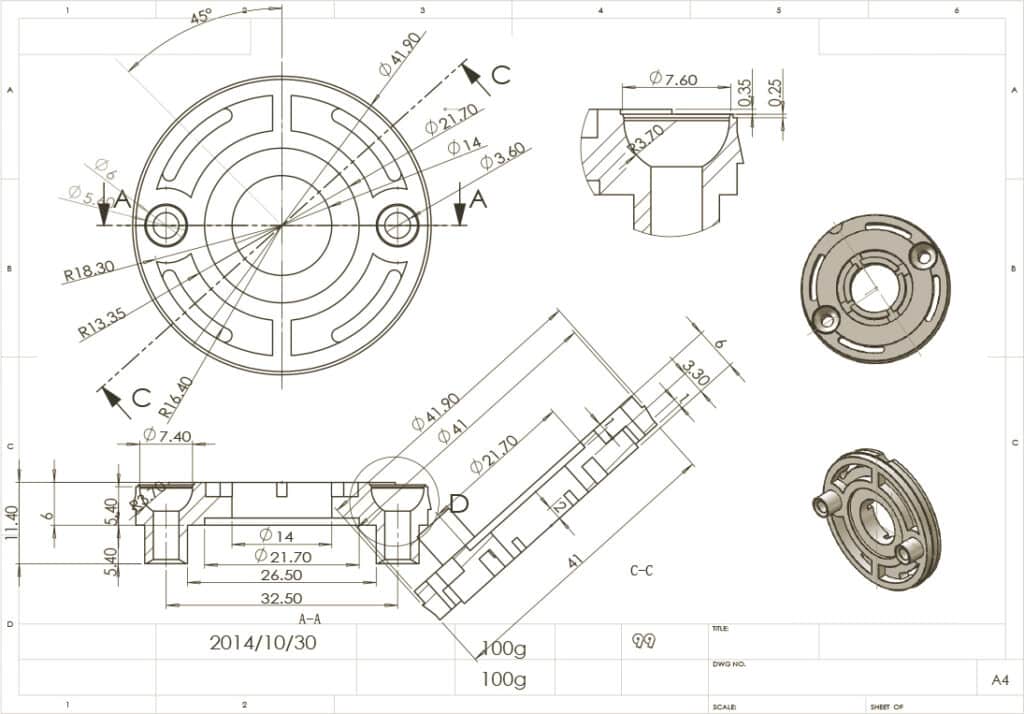

Ceramic injection molding is ideal for high-volume production of complex, tight-tolerance components, ceramic injection molding offers significant advantages over conventional…

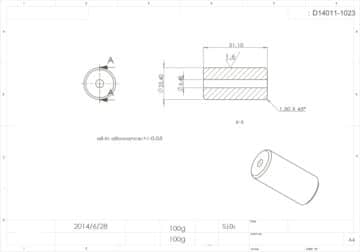

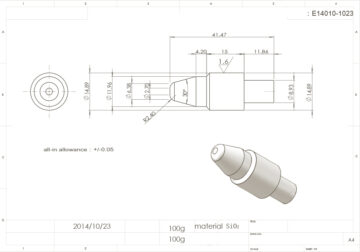

Ceramic plungers work exceptionally well for most saltwater, chemical, and metering applications.

Ortech specially-formulated grades of ceramic allow a standard 8 RMS surface…

Here at Ortech Advance Ceramics we have been manufacturing Aluminium oxide Al2O3 for over 20 years. Every single month we make 100’s …

Silicon nitride ceramics is superior to other materials due to its thermal shock resistance. It does not deteriorate at high temperatures…